How is uranium made into nuclear fuel?

Nuclear fuel pellets, with each pellet – not much larger than a sugar cube – contains as much energy as a tonne of coal (Image: Kazatomprom)

Uranium is the main fuel for nuclear reactors, and it can be found in many places around the world. In order to make the fuel, uranium is mined and goes through refining and enrichment before being loaded into a nuclear reactor.

The mining of uranium

Uranium is found in small amounts in most rocks, and even in seawater. Uranium mines operate in many countries, but more than 85% of uranium is produced in six countries: Kazakhstan, Canada, Australia, Namibia, Niger, and Russia.

Historically, conventional mines (e.g. open pit or underground) were the main source of uranium. After mining, the ore is crushed in a mill, where water is added to produce a slurry of fine ore particles and other materials. The slurry is leached with sulfuric acid or an alkaline solution to dissolve the uranium, leaving the remaining rock and other minerals undissolved.

However, over half of the world's uranium mines now use a method called in-situ leaching, where the mining is accomplished without any major ground disturbance. Water injected with oxygen (or an alkali, acid or other oxidizing solution) is circulated through the uranium ore, extracting the uranium. The uranium solution is then pumped to the surface.

The uranium solution from the mines is then separated, filtered and dried to produce uranium oxide concentrate, often referred to as ‘yellowcake’.

‘Yellowcake’ – one of the first steps towards making nuclear fuel (Image: Kazatomprom)

Enrichment

The vast majority of nuclear power reactors use the isotope uranium-235 as fuel; however, it only makes up 0.7% of the natural uranium mined and must therefore be increased through a process called enrichment. This increases the uranium-235 concentration from 0.7% to between 3% and 5%, which is the level used in most reactors.

A small number of reactors, most notably the CANDU reactors from Canada, are fuelled with natural uranium, which does not have to be enriched.

The enrichment process requires the uranium to be in a gaseous form. This is achieved through a process called conversion, where uranium oxide is converted to a different compound (uranium hexafluoride) which is a gas at relatively low temperatures.

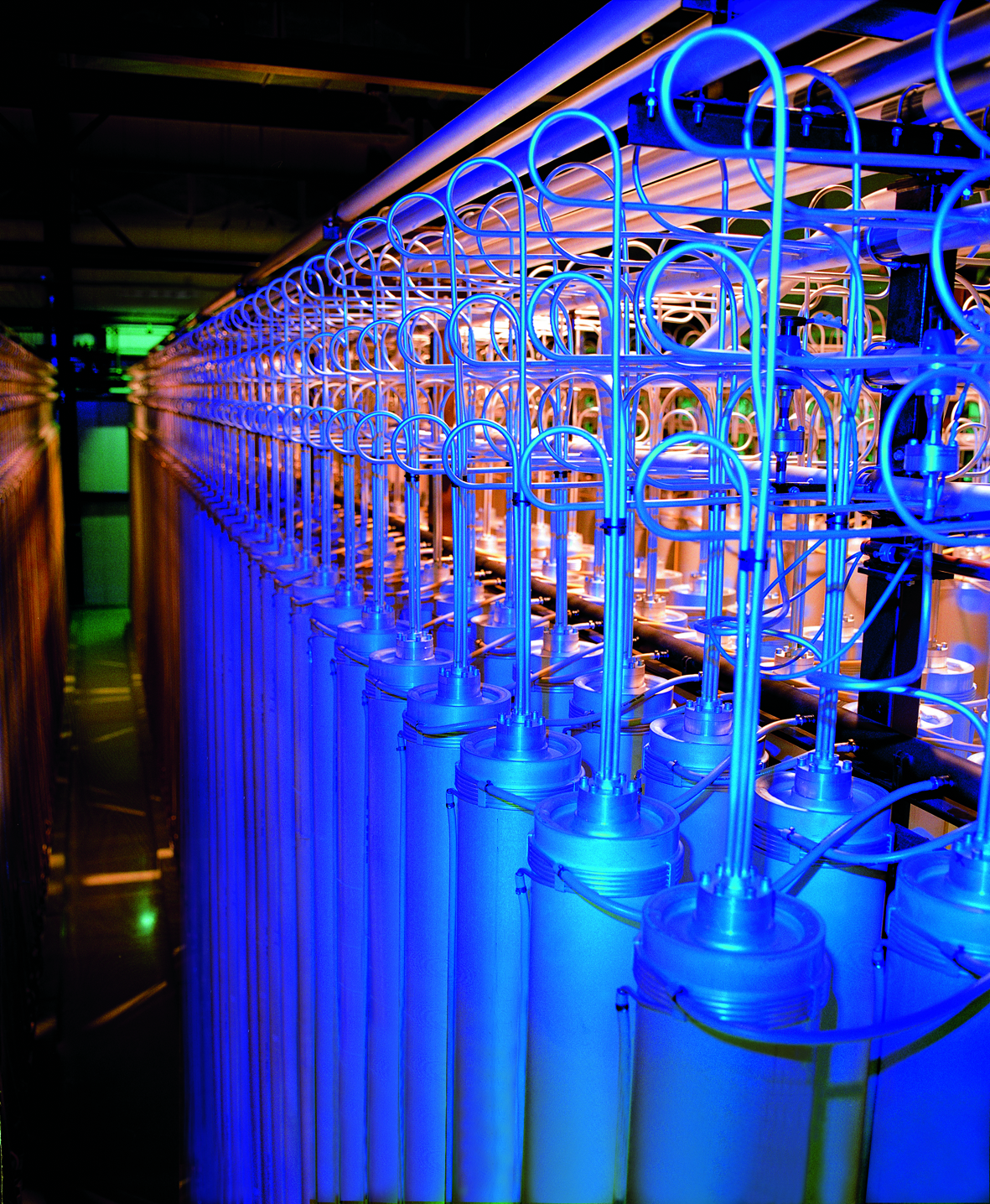

The uranium hexafluoride is fed into centrifuges, with thousands of rapidly-spinning vertical tubes that separate uranium-235 from the slightly heavier uranium-238 isotope. The centrifuges separate the uranium into two streams: one stream is enriched in uranium-235; the other consists of ‘tails’ containing a lower concentration of uranium-235, and known as depleted uranium (DU).

A bank of centrifuges at an enrichment plant (Image: Urenco)

The making of nuclear fuel

The enriched uranium is transported to a fuel fabrication plant where it is converted to uranium dioxide powder. This powder is then pressed to form small fuel pellets and heated to make a hard ceramic material. The pellets are subsequently inserted into thin tubes known as fuel rods, which are then grouped together to form fuel assemblies. The number of fuel rods used to make each fuel assembly ranges from around 90 to well over 200, depending on the type of reactor. Once loaded, the fuel normally stays in the reactor core for several years.

Nuclear fuel in its powder and pellet form (Image: Urenco)

About 27 tonnes of uranium – around 18 million fuel pellets housed in over 50,000 fuel rods – is required each year for a 1000 MWe pressurized water reactor. In contrast, a coal power station of equivalent size requires more than two and a half million tonnes of coal to produce as much electricity.

A fuel assembly, usually several metres long, can spend years in a reactor, generating immense amounts of low-carbon electricity (Image: Framatome)