Fast Neutron Reactors

- Fast neutron reactors (FNRs) are a technological step beyond conventional power reactors, but are poised to become mainstream.

- They offer the prospect of vastly more efficient use of uranium resources and the ability to burn actinides which are otherwise the long-lived component of high-level nuclear waste.

- Over 400 reactor-years of experience has been gained in operating them.

- Generation IV reactor designs are largely FNRs, and international collaboration on FNR designs is proceeding with high priority.

About 20 fast neutron reactors (FNR) have already been operating, some since the 1950s, and some supplying electricity commercially. Over 400 reactor-years of operating experience has been accumulated. Fast reactors more deliberately use the uranium-238 as well as the fissile U-235 isotope used in most reactors. If they are designed to produce more plutonium than the uranium and plutonium they consume, they are called fast breeder reactors (FBRs). But many designs are net consumers of fissile material including plutonium.* Fast neutron reactors also can burn long-lived actinides which are recovered from used fuel out of ordinary reactors.

* If the ratio of final to initial fissile content is less than 1 they are burners, consuming more fissile material (U-235, Pu and minor actinides) than they produce (fissile Pu), if more than 1 they are breeders. This is the burn ratio or breeding ratio. If the ratio is 1 they are iso-breeders, producing the same amount of fuel as they consume during operation.

Several countries have research and development programmes for improved fast neutron reactors, and the IAEA's INPRO programme involving 22 countries (see later section) has fast neutron reactors as a major emphasis, in connection with closed fuel cycle. For instance one scenario in France is for half of the present nuclear capacity to be replaced by fast neutron reactors by 2050 (the first half being replaced by EPR units).

Russia is at the forefront of fast reactor development. It operates the only commercial-scale fast reactors and is building a 300 MWe demonstration lead-cooled fast reactor. It also put lead-cooled fast reactors into its seven Alfa-class submarines, which was not a conspicuous success but yielded 70 reactor-years of experience.*

* These vessels with titanium hull were very fast but had operational problems in ensuring that the lead-bismuth coolant did not freeze (at 125°C) when the reactor was shut down. Reactors had to be kept running, even in harbour, since the external heating provision did not work. The design was unsuccessful and used in only eight trouble-plagued vessels, which were retired early – all but one in 1990.

An agreement between Japan's Atomic Energy Agency (JAEA), France's CEA and the US Department of Energy was signed in October 2010. This expanded previous FNR collaboration towards the joint design and development of reliable world-class FNRs and getting private manufacturers involved. JAEA is working on the design of a demonstration reactor to succeed the prototype FBR Monju, France was developing the Advanced Sodium Technical Reactor for Industrial Demonstration (ASTRID) with Japan, and wanted Japan to test its fuel in Monju. The USA has been focused on systems, materials and safety analysis with an extensive base of information and experiences as a result of past efforts to develop FNRs, notably the 400 MWt Fast Flux Test Facility (FFTF) and the 62.5 MWt Experimental Breeder Reactor II (EBR-II). It is now putting significant funding into two versions of GE Hitachi’s new PRISM, the Versatile Test Reactor and Natrium. PRISM was under serious consideration in the UK for burning its reactor-grade plutonium stockpile while producing electricity. Both pool-type and loop-type FNR designs are seen to have potential, though most larger designs are pool-type. The work will include FNR fuel cycles.

World fast neutron reactor status

Current FNRs

| Reactor | Type, coolant | Power, MW thermal/elec |

Fuel (future) |

Country | Notes |

|---|---|---|---|---|---|

| BOR-60 | Experimental, loop, sodium | 55/10 | oxide | Russia | 1969-2020s |

| BN-600 | Demonstration, pool, sodium | 1470/600 | oxide | Russia | 1980- |

| BN-800 | Experimental, pool, sodium | 2100/864 | oxide | Russia | 2014- |

| BREST | Demonstration, loop, lead | 700/300 | nitride | Russia | (2026) |

| FBTR | Experimental, pool, sodium | 40/13 | carbide (metal) | India | 1985-2030 |

| PFBR | Demonstration, pool, sodium | 1250/500 | oxide (metal) | India | (2022?) |

| CEFR | Experimental, pool, sodium | 65/20 | oxide | China | 2010- |

| Joyo | Experimental, loop, sodium | 140/- | oxide | Japan | 1978-2007, maybe restart 2021 |

FNR designs for near- to mid-term deployment – active development

| Reactor | Type, coolant | Power thermal/elec (MW) |

Fuel (future) |

Country | Notes |

|---|---|---|---|---|---|

| PRISM & Natrium | Demonstration, pool, sodium | 840/311 | metal | USA | From 2020s |

| ARC-100 | Prototype, pool, sodium | 260/100 | metal | USA | Working with GEH |

| Allegro | Experimental, loop, gas | 50-100 MWt | oxide (carbide) | Visegrád countries, with France | From 2030 |

| MYRRHA | Experimental, Pb-Bi | 57 MWt | oxide? | Belgium, with China | Early 2020s |

| ALFRED | Demonstration, lead | 300/120 | oxide | Romania, with Italy & EU | From 2025 |

| BN-1200 | Commercial, pool, sodium | 2800/1220 | oxide, nitride | Russia | From 2030 |

| MBIR | Experimental, loop, sodium (Pb-Bi, gas) |

100-150 MWt | oxide | Russia | From 2020, under const. |

| CDFR-600 | Demonstration, pool, sodium | 600 MWe | oxide | China | From 2023, under const. |

| CDFR-1000 | Commercial, pool, sodium | 1000-1200 MWe | metal | China | From 2034 |

| PGSFR | Prototype, pool, sodium | 392/150 | metal | South Korea | From 2028 |

| JSFR | Demonstration, loop (now pool), sodium | 500 MWe | oxide | Japan | From 2025? |

| TWR | Prototype, sodium | 600 MWe | metal | China, with USA | From 2023? |

| FBR 1&2 | Commercial, sodium | 600 MWe | oxide, metal | India | ? |

Small FNR designs under active development (particularly SMRs)

| Reactor | Type, coolant | Power thermal/elec (MW) |

Fuel (future) |

Company, country | Notes |

|---|---|---|---|---|---|

| PRISM | Demonstration, pool, sodium | 840/311 | metal | GEH, USA | From 2020s |

| ARC-100 | Prototype, pool, sodium | 260/100 | metal | ARC+GEH, USA | |

| FMR | Demonstration, helium HTR | 50 | ? | GA-EMS, USA | 2035 |

| EM2 | Helium HTR | 500/240 | oxide? | GA, USA | With MHI |

| Westinghouse LFR | Pool, lead | 950/450 | LEU oxide/silicide | Westinghouse, USA | |

| Moltex SSR-U | MSR | 750/300 (for 8 modules) | Pu+U chloride | Moltex UK | |

| Astrid | Prototype, pool, sodium | 100-200 | oxide | France, with Japan | Delayed, after 2050 |

| SVBR-100 | Demonstration, pool, Pb-Bi | 280/100 | oxide (variety) | Russia | Cancelled |

| Gen4 module | Lead-Bi | 70/25 | LEU nitride | Gen4, USA | |

| Sealer | Lead | 3-10 MWe | LEU oxide/nitride | LeadCold, Sweden | By 2025 |

| Aurora | Heatpipe | 4/1.5 | U-Zr metal | Oklo, USA | COL application |

| eVinci | Heatpipe | 0.2-5.0 MWe | various | Westinghouse, USA |

FNR history

The FNR was originally conceived to burn uranium more efficiently and thus extend the world's uranium resources – it could do this by a factor of about 60. From the outset, nuclear scientists understood that today's reactors fuelled essentially with U-235 exploited less than one percent of the energy potentially available from uranium. Early perceptions that those uranium resources were scarce caused several countries to embark upon extensive FBR development programs. However significant technical and materials problems were encountered, and also geological exploration showed by the 1970s that uranium scarcity would not be a concern for some time. Due to both factors, by the 1980s it was clear that FNRs would not be commercially competitive with existing light water reactors for some time.

Today there has been progress on the technical front, but the economics of FNRs still depends on the value of the plutonium fuel which is bred and used, relative to the cost of fresh uranium. Also there is international concern over the disposal of ex-military plutonium, and there are proposals to use fast reactors (as 'burners') for this purpose. In both respects the technology is important to long-term considerations of world energy sustainability.

Fast Neutron Reactors – historical and current

E = experimental, D = demonstration or prototype, C = commercial, R = research

| MWe | MW (thermal) | Operation | |

| USA | |||

|---|---|---|---|

| EBR 1 |

0.2

|

1.4

|

1951-63

|

| EBR II (E) |

20

|

62.5 |

1963-94

|

| Fermi 1 (E) |

61

|

200

|

1963-75

|

| SEFOR |

20

|

1969-72

|

|

| Fast Flux Test Facility (E) |

400

|

1980-93

|

|

| UK | |||

| Dounreay FR (E) |

15

|

65

|

1959-77

|

| Protoype FR (D) |

250

|

650

|

1974-94

|

| France | |||

| Rapsodie (E) |

40

|

1967-83

|

|

| Phenix* (D) |

250

|

563

|

1973-2009

|

| Superphenix (C) |

1240

|

3000

|

1985-98

|

| Germany | |||

| KNK 2 (E) |

20

|

58

|

1972-91

|

| India | |||

| FBTR (E) | 13 |

40

|

1985-

|

| PFBR (D) |

500

|

1250

|

under const.

|

| Japan | |||

| Joyo (E) |

|

50, 75, 140

|

1978-2007

2021 restart? |

| Monju (D) |

280

|

714

|

1994-96, 2010.

|

| Kazakhstan | |||

| BN-350* (D) |

135

|

750

|

1972-99

|

| Russia | |||

| BR 1/2 (E) | 1/0.1 | 1955, 1956 | |

| BR 5 Obninsk (R) |

5

|

1958-71

|

|

| BOR 60 Dimitrovgrad (R) |

12

|

60

|

1969-

|

| BR 10 Obninsk (R) | 8 | 1973-2002 | |

| BN-600* Beloyarsk 3 (D) |

600

|

1470 |

1980-

|

| BN-800 Beloyarsk 4 (E) | 864 | 2100 | 2014- |

| MBIR (E) | 40 | 150 | under const. |

| China | |||

| CEFR (E) | 20 | 65 | 2010- |

| CFR600 (D) | 600 | 1500 | under const. |

FNR operation

Natural uranium contains about 0.7% U-235 and 99.3% U-238. In any reactor some of the U-238 component is turned into several isotopes of plutonium during its operation. Two of these, Pu-239 and Pu-241, then undergo fission in the same way as U-235 to produce heat. In an FNR this process can be optimised so that it 'breeds' fuel. Some U-238 is burned directly with neutron energies above 1 MeV. Hence FNRs can utilise uranium about 60 times more efficiently than a normal reactor. They are however expensive to build and operate, including the reprocessing, and are only justified economically if uranium prices are reasonably high, or on the basis of burning actinides in nuclear wastes.

See also American Nuclear Society position statement (November 2005).

The fast reactor has no moderator and relies on fast neutrons alone to cause fission, which for uranium is less efficient than using slow neutrons. Hence a fast reactor usually uses plutonium as its basic fuel, since it fissions sufficiently with fast neutrons to keep going.* At the same time the number of neutrons produced per plutonium-239 fission is 25% more than from uranium, and this means that there are enough (after losses) not only to maintain the chain reaction but also continually to convert U-238 into more Pu-239. Furthermore, the fast neutrons are more efficient than slow ones in doing this breeding, due to more neutrons being released per fission. These are the main reasons for avoiding the use of a moderator. The coolant is a liquid metal (normally sodium) to avoid any neutron moderation and provide a very efficient heat transfer medium. So, the fast reactor 'burns' and 'breeds' fissile plutonium.** While the conversion ratio (the ratio of new fissile nuclei to fissioned nuclei) in a normal reactor is around 0.6, that in a fast reactor may exceed 1.0.

* high-enriched uranium (over 20% U-235) would fission, too. At this concentration of U-235, despite the low cross-section for fission with fast neutrons, fissions are sufficient to sustain the chain-reaction despite less likelihood of fission, so about 20% of fissile nuclei is required in the fuel. Up to 20% U is actually defined as 'low-enriched' uranium. The low cross-section is offset by more neutrons being released per fission above about 0.1 MeV.

** Both U-238 and Pu-240 are 'fertile' (materials), i.e. by capturing a neutron they become (directly or indirectly) fissile Pu-239 and Pu-241 respectively.

The conventional fast reactors built so far are generally fast breeder reactors (FBRs) implying a net increase in Pu-239 from breeding, due to a conversion ratio above 1.0. These have a 'fertile blanket' of depleted uranium (U-238) around the core, and this is where much of the Pu-239 is produced. Neutron activity is very low in the blanket, so the plutonium produced there remains almost pure Pu-239 – largely not burned or changed to Pu-240. The blanket can then be reprocessed (as is the core) and the plutonium recovered for use in the core, or for further FNRs. However, fast reactor concepts being developed for the Generation IV program will simply have a core so that the plutonium production and consumption both occur there. Russia’s BREST is the most advanced design. Conceptually, refuelling means simply adding a little natural or depleted uranium – about one or two percent of the total required for a comparable light water reactor. Due to the high radiation levels in the core, using simply a core and no blanket gives rise to some new challenges in how the fuel is fabricated and managed.

Many core configurations are possible, but for maximum breeding, the conventional core plus blanket arrangement is best. If a breeding ratio of less than 1, or just a little more than 1 is wanted, then axial blankets which are included in the fuel pins will serve the purpose. The entire fuel pins are then reprocessed, and the newly-formed plutonium is mixed with the used fuel materials from the fissile zone of the pins. It is also possible to have a uniform core without separate U-238, and with stainless steel reflectors, but little breeding is then possible.

Theoretically any fast reactor can be operated over a spectrum from burner (with steel reflectors around the core) to breeder (with U-238 blanket around the core). Operation of the BN-600 reactor to burn weapons-grade plutonium from 2012, means that the breeding blanket of depleted uranium is removed and replaced by stainless steel reflector assemblies.

India’s three-stage thorium fuel cycle is unique, and still under development (see next section). Here, fast breeder reactors form stage 2 and use plutonium-based fuel in the core to breed both U-233 from thorium and Pu-239 from U-238 in the blanket. The plutonium and U-233 is needed as a driver fuel in advanced heavy water reactors forming stage 3 of the concept – these get about 75% of their power from the thorium, but need the plutonium and U-233 to do so.

The core of a fast reactor is much smaller than that of a normal nuclear reactor, and it has a higher power density, requiring very efficient heat transfer. For instance, the core of Russia's BN-600 reactor (560 MWe) is 0.88 metres active height and 0.75 m diameter. The BN-800 core is similar, and the BN-1200 core is only 0.85 m high. Fuel may be enriched uranium oxide (BN-350, BN-600, BN-800) or MOX (BOR-60, BN-800, BN-1200 initially). BREST will use a high-density U+Pu nitride fuel with no requirement for high enrichment levels. BN-1200 will use nitride fuel also.

One effect of the 1980s halt to FNR development is that separated plutonium (from reprocessing used light water reactor fuel) which was originally envisaged for FNRs is now being used as mixed oxide (MOX) fuel in conventional reactors.

Fast neutron reactors have a high power density and are normally cooled by liquid metal such as sodium, lead, or lead-bismuth eutectic, with high conductivity and boiling point and no moderating effect. They operate at around 500-550°C at or near atmospheric pressure. Fast reactors typically use boron carbide control rods.

In some respects a liquid metal coolant is more benign overall than very high pressure water, which requires robust engineering on account of the pressure. However, the design needs to ensure that there is no chemical interaction (e.g. sodium-water), and as it is lead-cooled, the materials used need to allow for molten lead being very corrosive. Russian BN reactors have argon as inert gas above the sodium coolant. Russia is building a 300 MWe lead-cooled fast reactor. Some future plans are for gas-cooled fast reactors. Lead or lead-bismuth cooled fast reactors include MYRRHA, ALFRED and BREST. Russia’s MBIR now under construction is to be cooled by lead or lead-bismuth, gas and sodium simultaneously (details below).

Lead or lead-bismuth eutectic in fast neutron reactors are capable of high temperature operation at atmospheric pressure. Pb-208 – 54% of naturally-occurring lead – is transparent to neutrons. This means that efficiency is better due to greater spacing between fuel pins which then allows coolant flow by convection for decay heat removal. Lead and lead-bismuth have much higher thermal conductivity than water, but lower than sodium. In 1998 Russia declassified a lot of research information derived from its experience with lead-bismuth in submarine reactors, and US interest in using lead generally or lead-bismuth for small reactors has increased subsequently.

According to OKBM, the fundamental difference between the lead-bismuth-cooled reactor and the sodium-cooled reactor is that the lead-bismuth reactor limits plutonium production. Only the sodium reactor has a breeding ratio much greater than 1 (~1.3), which both allows it to expand its own fuel cycle and become a fuel supplier for the future power industry.

See also section on Primary coolants in the information page on Nuclear Power Reactors.

Also fast reactors have a strong negative temperature coefficient (the reaction slows as the temperature rises unduly), an inherent safety feature, and the basis of automatic load following in many new designs.

Experiments on a 19-year old UK breeder reactor before it was decommissioned in 1977, and on EBR-II in the USA in 1986, showed that the metal fuel with liquid sodium cooling system made them less sensitive to coolant failures than the more conventional very high pressure water and steam systems in light water reactors. More recent operating experience with large French and UK prototypes has confirmed this. With loss of coolant flow they simply shut themselves down.

There is renewed interest in fast reactors due to their ability to fission actinides, including those which may be recovered from ordinary reactor used fuel. The fast neutron environment minimises neutron capture reactions and maximises fissions in actinides. This means less long-lived nuclides in high-level wastes (the fission products being preferable due to shorter lives). Also the fast neutron environment is required for fissioning even-numbered isotopes of uranium, not only U-238 but also others which may be significant in recycled uranium.

Transmutation probabilities (%)

| Isotope | thermal spectrum | fast spectrum |

| Np-237 | 3 | 27 |

| Pu-238 | 7 | 70 |

| Pu-239 | 63 | 85 |

| Pu-240 | 1 | 55 |

| Pu-241 | 75 | 87 |

| Pu-242 | 1 | 53 |

| Am-241 | 1 | 21 |

| Am-242m | 75 | 94 |

| Am-243 | 1 | 23 |

| Cm-242 | 1 | 10 |

| Cm-243 | 78 | 94 |

| Cm-244 | 4 | 33 |

Chang 2014

Fast research reactors

Nearly all of the world’s research reactors operate with thermal (slow) neutrons; Russia claims that its BOR-60 at Dimitrovgrad is the only fast neutron research reactor.* It started up in 1969 and is to be replaced after the end of 2020 with the MBIR, with four times the irradiation capacity. There is a world shortage of fast reactor research capacity, especially for fast neutron materials testing for Generation IV reactor developments.

In February 2019 the US Department of Energy launched its Versatile Test Reactor (VTR) programme, set up under the Nuclear Energy Innovation Capabilities Act 2017 and run by the Idaho National Laboratory. The VTR project is to be a research facility for testing of advanced nuclear fuels, materials, instrumentation and sensors. It is to provide accelerated neutron damage rates 20 times greater than current water-cooled test reactors. GE Hitachi's PRISM will be adapted as a test reactor under this programme for R&D. Operation is planned by the end of 2025.

* Several small experimental reactors – CEFR, FBTR, Joyo – fall into the broad category of research reactors in that they are not designed to produce power for the grid, but they do not generally operate as neutron irradiation and research facilities for third parties (although CEFR may do so to some extent).

Fast reactor fuel cycles

Reprocessing used fuel, and especially the blanket assemblies, is fundamental to the FBR fuel cycle. Typically the recovered plutonium from aqueous reprocessing is incorporated into the core as MOX fuel and any surplus deployed elsewhere. The general principles of this are described above. In France about 25 tonnes of fuel from Phenix was reprocessed and the plutonium incorporated into fresh fuel elements, some of it recycled three times.

However, with the transition from core and blanket designs to integrated core designs, it is likely that used fuel will be reprocessed using electrometallurgical processes (so-called pyro-processing) and plutonium will not be separated but will remain with other transuranics and some highly radioactive fission products. Pyroprocessing has several advantages for fast reactors which greatly simplify waste management and closing the fuel cycle.

A generalised picture of fast reactor fuel cycle is two-stage separation of uranium then transuranics, leaving most fission products as a small waste stream. Some or all of the uranium, and the transuranics (including plutonium and minor actinides), are recycled.

See also information page on Processing of Used Nuclear Fuel.

India's nuclear power program has been focused on developing an advanced heavy-water thorium cycle, based on converting abundant thorium-232 into fissile uranium-233. The first stage of this employs PHWRs fuelled by natural uranium, and light water reactors, to produce plutonium. Stage two uses fast neutron reactors burning the plutonium to breed U-233 from thorium. The blanket around the core will have uranium as well as thorium, so that further plutonium (ideally high-fissile Pu) is produced as well as the U-233. Then in stage three, advanced heavy water reactors burning the U-233 and this plutonium as driver fuels, but utilising thorium as their main fuel, and getting about two-thirds of their power from the thorium.

The 500 MWe Prototype Fast Breeder Reactor (PFBR) started construction in 2004 at Kalpakkam near Madras. It was expected to start up about the end of 2010 and produce power in 2011, but this schedule was delayed significantly. In 2014, 1750 tonnes of sodium coolant was delivered. With construction completed, in June 2015 Bhavini was "awaiting clearance from the AERB for sodium charging, fuel loading, reactor criticality and then stepping up power generation." Criticality was expected in 2018. The approved cost is Rs 5677 crore. It is not under IAEA safeguards. The reactor is fuelled with uranium-plutonium oxide. It has a blanket with thorium and uranium to breed fissile U-233 and plutonium respectively.

Fast reactor fuel types

Oxide (UO2-20PuO2) has low thermal conductivity and a low density of fissile atoms but it does not react with lead or sodium. It is well-known in all the main countries.

Metal (U-20Pu-10Zr) has very high thermal conductivity compared with oxide, but high swelling and melts at a relatively low 1160°C. It is not compatible with lead coolant, due to solubility (in case of cladding failure). It is being researched in Russia, USA, and Japan, and is planned for early use in Russia where it is seen to have the best safety characteristics for lead-cooled reactors.

Nitride (UN-20PuN) has high thermal conductivity (ten times that of oxide) and high density of fissile atoms but is subject to swelling and C-14 contamination (from N-14 + neutron). To avoid this pure N-15 is needed, which requires enrichment. It is being researched in USA, Russia and Japan.

Carbide (UC-10PuC) has high thermal conductivity and a high density of fissile atoms, but high swelling and poor compatibility with air and water. There are several types of carbide fuels, such as UC, UC2, U2C3 and (U, Pu)C. Research is being pursued in India. Its FBTR has run on mixed carbide fuel since 1985 (70% PuC, 30% UC).

The production of both nitride and carbide fuels is more complex than MOX or metal fuels.

(Source: Vattenfall, 2011 & 2012)

Some of the new small FNRs have other kinds of fuel such as chlorides dissolved in molten salt, or silicides.

A reprocessing centre for thorium fuels is being set up at Kalpakkam in India.

FNR developments in Europe

Phenix & Superphenix

France operated its Phenix fast reactor prototype from 1973 to 2009, apart from a few years for refurbishing. It ceased generating power early in 2009 but ran until October 2009 as a research reactor. Closure of the 1250 MWe commercial prototype Superphenix FBR in 1998 on political grounds after very little operation over 13 years set back developments. Research work on the 1450 MWe European FBR has apparently ceased.

Phénix operation was geared towards achieving the highest possible fuel burnup (which is incompatible with weapons-grade Pu production). All the plutonium which was produced was recycled back into the reactor after reprocessing. Phenix was designated as a Nuclear Historic Landmark in 1997 by the American Nuclear Society. The following is from the definitive biography of Phénix (J-F Sauvage, CEA):

"After preliminary operations on fuel reprocessing, the first campaigns began in December 1976 in CEA’s Marcoule Pilot Plant, for direct reprocessing. To 1983, the facility reprocessed 9 tonnes of Phénix spent fuel with irradiation level up to 80,000 MWd/t. The Cogéma plant in La Hague (UP2 - 400) reprocessed approximately 10 tonnes of used fuel between 1979 and 1984 (diluted with the fuel from the GCR reactors). In all, the equivalent of four-and-a-half cores from the Phénix plant have been reprocessed, which accounts for 25 tonnes of fuel."

The plutonium which was recovered was recycled to make new fuel, and sub-assemblies with this being used in the core from 1980. Some of these elements have been re-reprocessed at the Marcoule Pilot Plant. Thus, the Phénix plant has performed the fuel cycle loop several times, clearly proving the value of the breeder reactor system.

The breeding ratio planned for Phénix was 1.13, though measurements showed an actual value closer to 1.16, so that 16% more fissile fuel was created than was used. This entire experience, involving reprocessing high specific burn-up fuels, waste confinement and closed fuel cycle, is claimed by CEA to be unique, and proving the fast breeder reactor fuel cycle as an industrial reality.

From the start, the reactor core was reloaded the equivalent of 7 times, with more than 700 fissile sub-assemblies, of which nearly 200 were experimental, or 140,000 fuel pins.

To this must be added the several hundred breeder sub-assemblies where the plutonium forms. A radial breeder blanket of depleted uranium oxide is in about one hundred sub-assemblies, with each assembly containing 61 fuel pins 1.8 m long. The structural elements of these sub-assemblies are identical to those used in the fissile assemblies. A breeder assembly contains 2 kg of plutonium after irradiation, has a mass of 294 kg and retains the same overall dimensions of those of a fissile fuel sub-assembly.

The fuel reached a specific burn-up of 90,000 MWd/t at the centre of the core and 115,000 MWd/t at the periphery. Experimental pins and sub-assemblies reached specific burn-up values of about 150,000 MWd/t, three times more than the design values.

ASTRID

In mid-2006 the French Atomic Energy Commission (CEA) was commissioned by the government to development two types of fast neutron reactors which are essentially Generation IV designs: an improved version of the sodium-cooled type (SFR) which already has 45 reactor-years of operational experience in France, and an innovative gas-cooled type – Allegro. Both would have fuel recycling, and in mid-2009 it was recommended that the sodium-cooled model, Astrid (Advanced Sodium Technological Reactor for Industrial Demonstration), should be a high priority in R&D on account of its actinide-burning potential. The CEA sought support under the EC's European Sustainable Nuclear Industrial Initiative (ESNII) to develop the SFR which will have great flexibility in breeding ratios. It noted that China and India are aiming for high breeding ratios to produce enough plutonium to crank up a major push into fast reactors. In May 2014 Japan committed to support Astrid development, and in August 2014 the Japan Atomic Energy Agency (JAEA), Mitsubishi Heavy Industries and Mitsubishi FBR Systems concluded a five-year agreement with the CEA and Areva (now Framatome) to progress cooperation on Astrid. After CEA's Astrid programme was put on hold in August 2019, in January 2020 a second five-year agreement on the development of fast neutron reactors took effect.

Astrid was initially envisaged as a 600 MWe prototype of a commercial series of 1500 MWe SFR reactors which was planned to be deployed from about 2050 to utilise the abundant depleted uranium (DU) available by then (France alone will have half a million tonnes) and also burn the plutonium in used MOX fuel. Astrid is planned to have high fuel burn-up, including minor actinides in the fuel elements, and while the MOX fuel will be broadly similar to that in PWRs, it will have 25-35% plutonium and negative void reactivity in the core. It will use an intermediate sodium coolant loop, and the tertiary coolant in the power conversion system (PCS) was planned to be nitrogen with Brayton cycle, subject to review. The gas PCS avoids any potential water interface with sodium, though steam/water PCS remains an alternative. Over 2014-16 experiments with Brayton cycle gas turbine technology driven by nitrogen were carried out with the CEA. Four independent heat exchanger loops are likely, each with two heat exchangers, and it will be designed to reduce the probability and consequences of severe accidents to an extent that is not now done with FNRs. The reactor core will leak neutrons, which reduces fissile breeding ability but gives it a negative reactivity coefficient to improve safety. Astrid is called a 'self-generating' fast reactor rather than a breeder in order to demonstrate low net plutonium production. Astrid is designed to meet the criteria of the Generation IV International Forum in terms of safety, economy and proliferation resistance. CEA plans to build it at Marcoule.

In September 2010 the French government confirmed its support, and €651.6 million funding to 2017, for a 1500 MWt, 600 MWe Astrid prototype. (A further €350 million was later approved to 2020.) In December 2012 it approved moving to the design phase, with a final decision on construction to be made in 2019. The six-year conceptual design was finished in 2015. The basic design phase ran to 2019, with 14 industrial partners. The CEA is responsible for the project and will design the reactor core and fuel, but will collaborate with Areva, which will design the nuclear steam supply system, the nuclear auxiliaries and the instrumentation and control system. Japanese partners have been playing a major role since 2015.

According to a February 2010 study by Deloitte for the EU's Strategic Nuclear Energy Technology Platform, a 600 MWe sodium-cooled fast reactor would cost €4.286 billion, with most of the financing coming from European institution loans, EU incentives and grants such as the EC's European Sustainable Nuclear Industrial Initiative (ESNII), plus €839 million from private investors.

The Astrid programme includes development of the reactor itself and associated fuel cycle facilities: a dedicated MOX fuel fabrication line (AFC) was to be built about 2017 and a pilot reprocessing plant for used Astrid fuel (ATC) about 2023. Fuel rods containing actinides for transmutation were scheduled to be produced from 2023, though fuel containing minor actinides would not be loaded for transmutation in Astrid before 2025. In May 2014 Japan (MEXT & METI) committed to support Astrid development, and in August 2014 JAEA, Mitsubishi Heavy Industries and Mitsubishi FBR Systems concluded an agreement with the CEA and Areva NP to progress cooperation on Astrid. In 2015 JAEA with MHI-MFBR became the second largest contributor to the programme, after Areva NP (now Framatome). In March 2017 the Japanese partnership was strongly reaffirmed after Japan decided to decommission its Monju FNR. In October 2017 the CEA signed an agreement with Russia's Research Institute of Atomic Reactors (RIAR) to use its BOR-60 fast research reactor for materials testing for Astrid.

In June 2018 the French government said that Astrid would have its capacity scaled down from the initially planned 600 MWe to between 100 and 200 MWe to reduce construction costs and also due to development of a commercial fast reactor no longer being a high priority. Following the decision, Toshiba said that the smaller Astrid would be a step back for Japan's fast reactor development process, possibly forcing the country to build its own larger demonstration reactor in Japan rather than rely on Astrid. In August 2019 the CEA said it no longer planned to build the prototype Astrid reactor in the short or medium term.

In December 2019 a new agreement to cooperate in FNR development was signed by the CEA, Framatome and the Japanese Astrid partners: JAEA, Mitsubishi FBR Systems and Mitsubishi Heavy Industries. JAEA said that this five-year agreement would focus on safety, after the earlier joint R&D efforts made progress on fuel, severe accidents and other technology areas, and moved the Japanese plans from loop to pool-type technology.

Allegro

Allegro was the second line of French-led FNR development – also a Euratom project under the European Sustainable Nuclear Industrial Initiative (ESNII). It is now the demonstration project for the reference gas-cooled fast reactor (GFR), one of the six or seven designs promoted by the Generation IV International Forum. A 50-100 MWt experimental version would initially have a MOX or UO2 driver core with outlet temperature of 530 °C, then an intermediate core with up to six refractory mixed carbide fuel assemblies, then a final refractory carbide core with 850 °C outlet temperature. Two primary helium circuits connect to secondary circuits with gas or pressurized water. Three decay heat removal loops are integrated in a pressurized guard vessel. The Czech Republic, Hungary, Slovakia and Poland (i.e. the Visegrád countries) made a joint proposal to host the project, with French CEA support, and the V4G4 Centre of Excellence was set up in Slovakia in 2015 (V4G4 = Visegrád 4, Generation IV). The project’s preparatory phase is planned to 2026.

The objectives of the Allegro project are:

- To determine the feasibility of the GFR as an alternative to the sodium-cooled fast reactor.

- Pilot-scale demonstration of key GFR technologies – validated safety reference framework.

- Fast flux irradiation – fuel development incorporating minor actinides.

- To test the capacity of high-temperature components and heat processes.

Allegro is planned as a demonstration plant for the 2400 MWt GFR envisaged by the Generation IV International Forum. It would be a combined cycle plant, with secondary helium-nitrogen (20%-80%) circuit at 820 °C driving a gas turbine and then supplying three steam generators.

In May 2021 the Czech nuclear research institute, UJV Rez, announced its project to design by 2035 a fourth-generation high-temperature gas-cooled reactor aimed at the heating and industrial sectors. Based on Allegro, this Hefasto (helium-cooled fast reactor) project is to develop a 200 MWt reactor operating at up to 900°C. Three versions will be pitched to heating, cogeneration and the chemical industry.

The GFR concept avoids the coolant handling issues associated with liquid metal-cooled fast reactors: helium primary coolant is chemically inert and does not become activated, also being transparent it permits simple inspection and repair. The GFR offers a high temperature heat source for high efficiency electricity generation and high quality process heat. The main technical challenges lie in the development of a high-temperature, high-power density fuel and in the development of a robust decay heat removal system.

MYRRHA

The European Sustainable Nuclear Industrial Initiative (ESNII), brings together industry and research partners in the development of Generation IV Fast Neutron Reactor technology, as part of the EU's Strategic Energy Technology Plan (SET-Plan). ESNII was set up under the umbrella of the Sustainable Nuclear Energy Technology Platform (SNETP), formed in 2007 and bringing together more than 90 stakeholders involved in nuclear fission.

Belgium's SCK.CEN is planning to build the MYRRHA (Multipurpose Hybrid Research Reactor for High-tech Applications) research reactor at Mol. Initially it will be a 57 MWt accelerator-driven system (ADS), consisting of a proton accelerator delivering a 600 MeV, 2.5 mA (or 350 MeV, 5 mA) proton beam to a liquid lead-bismuth (Pb-Bi) spallation target that in turn couples to a Pb-Bi cooled, subcritical fast nuclear core. As an ADS it will be used to prove that technology and to study transmutation of long-lived radionuclides in nuclear waste. Later on it is intended to be run as a critical fast neutron facility, decoupling the accelerator and removing the spallation loop from the reactor core. Then MYRRHA (as a lead-bismuth-cooled fast reactor – LFR) will be used for fuel research, for materials research for Generation IV reactors, and for the production of radioisotopes and doped silicon (an essential component of high-grade electronic circuits). From the early 2020s it will be the technology pilot for ALFRED.

It is envisaged as a partnership of Belgium, the European Union, the European Investment Bank and other partners, with 70% of the funding from EU countries under ESNII. Following an independent international evaluation, Belgium approved its 40% share of the funding in March 2010 – about €384 million – which puts the project on course for construction start in 2015 and operation about 2023. In October 2010 SCK-CEN signed two international agreements to collaborate on the Myrrha project. The first is with the China Academy of Sciences, since China sees as Myrrha a way forward in treating nuclear wastes. The second is with Kazatomprom and the Kazakh National Nuclear Centre (NNC). A reduced-power model, Guinevere, became operational at Mol in March 2010.

ALFRED

ESNII also includes a 300 MWt, 120-125 MWe LFR technology demonstrator – the Advanced Lead Fast Reactor European Demonstrator (ALFRED), seen as a prelude to a prototype LFR (PROLFR) of 300-400 MWe online about 2035, and then an industrial scale unit of about 600 MWe (European Lead-cooled Fast Reactor, ELFR). It was intended that construction on ALFRED would begin in 2017 and the unit could start operating in 2025. ALFRED will employ mixed-oxide (MOX) fuel, with about 17% plutonium in equilibrium, and able to recycle minor actinides as about 1% of feed. First core would be 82.5% U, 17.5% Pu, and top up will then be about 1 gram of natural uranium per MW day. Fission products will be removed at that rate. Equilibrium MOX level will be about 17%. Phase 1 operation would be low temperature and low power; phase 2 to about 2040 would be at high temperature – around 550°C – and full power using materials qualified in phase 1. It features passive safety systems.

A consortium was set up in December 2013 for its construction, comprising Italy's National Agency for New Technologies, Energy and the Environment (ENEA), Ansaldo Nucleare, and Romania's Nuclear Research Institute (Institutul de Cercetari Nucleare, ICN). The group is to be known as the Fostering Alfred Construction (Falcon) consortium, which will be expanded through the participation of further European organizations. The total cost of the project is put at some €1.0 billion. ALFRED will be built at ICN's facility in Mioveni, near Pitesti in southern Romania, where a fuel manufacturing plant is in operation for the country's two operating Candu reactors.

ELSY

In Europe, the European Lead-cooled System (ELSY) of 600 MWe is led by Ansaldo Nucleare from Italy and earlier financed by Euratom. ELSY is a flexible fast neutron reactor design to use depleted uranium or thorium fuel matrices, and burn actinides from LWR fuel. Liquid metal (Pb or possibly Pb-Bi eutectic) cooling is at low pressure. The design was nearly complete in 2008 and a small-scale demonstration facility was planned. It runs on MOX fuel at 480°C and the molten lead is pumped to eight steam generators, though decay heat removal is passive, by convection. It has been superseded by ALFRED, but Ansaldo Nucleare continues work on the concept in China.

UK

In the UK, the Dounreay Fast Reactor started operating in 1959 using sodium-potassium coolant. This was followed there by the much larger Prototype Fast Reactor which operated for 20 years until the government withdrew funding.

Russian FNR developments

Rosatom plans to invest its own funds into FNR development through to 2025. In October 2018 it asked the government to allocate an additional RUR 200 billion (about $3 billion) over 2019-2025 under the federal target programme for nuclear power. BREST appears to be the focus of this.

BN series

The Russian BN-600 fast breeder reactor – Beloyarsk unit 3 of 600 MWe gross, 560 MWe net – has been supplying electricity to the grid since 1980 and is said to have the best operating and production record of all Russia's nuclear power units. It uses chiefly uranium oxide fuel, enriched to 17, 21 & 26%, with some MOX in recent years. It is a pool-type, with heat exchanger for three secondary coolant loops inside a pool of sodium around the reactor vessel and three steam generators outside the pool, supplying three 200 MWe turbine generators. The sodium coolant delivers 525-550°C at little more than atmospheric pressure. The BN-600 is reconfigured by replacing the fertile blanket around the core with steel reflector assemblies to burn the plutonium from its military stockpiles. Its licence has been extended to 2020 and a further five-year extension is envisaged.

The BN-350 prototype FBR generated power in Kazakhstan for 27 years to 1999 and about half of its 1000 MW(thermal) output was used for water desalination. It used uranium enriched to 17-26%. Its design life was 20 years, and after 1993 it operated on the basis of annual licence renewal. Russia's BOR-60 was a demonstration model preceding it, with 45-75% enriched MOX fuel. Both these are loop-type units with two sets of heat exchangers outside the reactor vessel. BN-350 had five operating primary and secondary sodium coolant loops.

The BN-800 from OKBM Afrikantov and Atomenergoproekt is a new more powerful (2100 MWt, 864 MWe gross, 789 MWe net) three-loop pool type FBR, which is actually the same overall size and configuration as the BN-600 except that the three steam generators drive a single turbine generator. There are some significant improvements from BN-600 however. The first (and probably only Russian one) is Beloyarsk 4, which started up in mid-2014. It has improved features including fuel flexibility – U+Pu nitride, MOX, or metal, and with breeding ratio potentially up to 1.3, though only 1.0 as configured at Beloyarsk. The MOX is quoted as having 20-30% fissile isotopes. However, during the plutonium disposition campaign it is being operated with a breeding ratio of less than one. Russia had about 40 tonnes of separated plutonium stockpiled by 2010, which was expected to be burned in the BN-800 by 2025. The timing of this has slipped about four years.

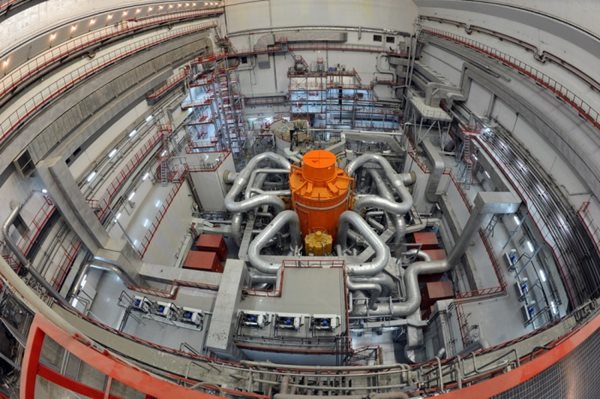

Inside the Beloyarsk 4 reactor building (Rosatom)

The initial BN-800 fuel was designed to be MOX, but due to delayed supplies it was initally about 80% uranium oxide plus up to 100 vibropacked MOX assemblies and 66 pelletised MOX ones (of 565 total). The average plutonium content in the MOX fuel will be 22%. By the end of 2021 it will have a full MOX core. It does not have a breeding blanket, though a version designed for Sanming in China allows for up to 198 DU fuel elements in a blanket. It has three loops containing 910 t sodium in total, outlet primary coolant temperature is 547°C. The secondary circuit also uses sodium, at 505°C to give steam temperature 470°C. Service life is 40 years. Net thermal efficiency is 39.35% and average fuel burnup is 66 GWd/t with potential increase to 100 GWd/t. It has much enhanced safety and improved economy – while capital cost is 20% more than VVER-1200, operating cost is expected to be only 15% more than VVER. It is capable of burning up to 3 tonnes of plutonium per year from dismantled weapons (1.7 t/yr also quoted by OKBM Afrikantov) and will test the recycling of minor actinides in the fuel.

An important feature of BN-800 closed-loop fuel cycle is that actinides (both plutonium and minor actinides) produced in the reactor are consumed in the same reactor. The reactor fuel cycle in equilibrium accommodates about 5 t plutonium (including 3 t in the core and 2 t in the external fuel cycle), and about 200 kg minor actinides. It is assumed that the reactor core would be recycled 20 times in 40 years of service life, based on 730 equivalent days of a fuel campaign. The main purpose of the BN-800 is to provide operating experience and technological solutions, especially regarding the fuel, that will be applied to the BN-1200.

In 2009 two BN-800 reactors were sold to China. Construction at Sanming is delayed from intended start in 2013 and may happen after 2020.

The BN-1200 fast reactor is being developed by OKBM Afrikantov in Zarechny as a next step towards Generation IV designs, and the design was expected to be complete by 2016. Rosenergoatom is ready to involve foreign specialists in its project, with India and China particularly mentioned. Rosatom's Science and Technology Council has approved the BN-1200 reactor for Beloyarsk, with plant operation from about 2025. A second one will be built at South Urals by 2030. It is significantly different from preceding BN models (four-loop rather than three-loop, being one aspect), and Rosatom plans to submit the BN-1200 to the Generation IV International Forum (GIF) as a Generation IV design.

It will be 2800 MW thermal at 550°C, giving 1220 MWe gross and 60-year lifetime (30 years for steam generators), with burn-up of up to 120 GWd/t (average 90 GWd/t for nitride, 112 for MOX). Intermediate heat exchanger temperature 550°C, with 527°C in secondary sodium circuit and 510°C outlet at 17 MPa from steam generators which represent an advanced design. Thermal efficiency is 43.5% gross, 40.7% net. Simplified refuelling is on a 330-day cycle (cf 155 days for BN-800). The initial loading of fissile plutonium isotopes is 7.5 tonnes, usage per year 8.74 tonnes of fuel, including 1.39 tonnes of plutonium. Fuel loading is 47 t of MOX, or 59 t nitride. Concentration of fissile plutonium is 16%. Core breeding ratio was intended to be 1.2 initially with MOX fuel, later 1.35, and then 1.45 with nitride fuel, but has been reduced to about 1, with nitride fuel. Fuel burn-up is designed to progress from 14.3% to 21%. It would have 426 fuel assemblies and 174 radial blanket assemblies surrounded by 599 boron shielding assemblies. Spent fuel assemblies would be stored in the reactor for two years.

The BN-1200 is part of a federal Rosatom program, the Proryv (Breakthrough) Project for large fast neutron reactors. Since about 2015 the focus for the BN-1200 has been increased safety and reduced capital costs, resulting in reduced power density in the reactor core, reduced core breeding ratio and a focus on nitride fuel. A lead-cooled version of the BN-1200 is under development. OKBM envisages about 11 GWe of such plants by 2030, including the South Urals nuclear plant.

To follow the BN series, Rosatom put forward two fast reactor implementation options for government decision in relation to the Advanced Nuclear Technologies Federal Program 2010-2020. The first focused on a lead-cooled fast reactor such as BREST with its fuel cycle, and assumed concentration of all resources on this project with a total funding of about RUR 140 billion (about $3.1 billion). The second scenario assumed parallel development of fast reactors with lead, sodium and lead-bismuth coolants and their associated fuel cycles, including the multi-purpose small MBIR. It would cost about RUR 165 billion ($4.7 billion). The second option was designed to attract more funds apart from the federal budget allocation, was favoured by Rosatom, and was accepted. It provides a technological basis of the future innovative nuclear energy system featuring the Generation IV reactors working in closed fuel cycles by 2020.

BREST

Russia has experimented with several lead-cooled reactor designs, and used lead-bismuth cooling for 20 years to the 1990s in reactors for its seven Alfa-class submarines. A significant new Russian design from NIKIET is the BREST fast neutron reactor, of 700 MWt, 300 MWe with lead as the primary coolant, at 540 °C, and supercritical steam generators. It is inherently safe and uses a mixed uranium and plutonium nitride fuel, the fuel load being 20.6 t. No weapons-grade plutonium can be produced, since there is no uranium blanket – all the breeding occurs in the core. The core breeding ratio is 1.05. Effective enrichment is about 13.5%. Fuel cycle is quoted at 5-6 years with partial refuelling at about 10 months. The initial cores can comprise plutonium and spent fuel – hence loaded with fission products, and radiologically 'hot'. Subsequently, any surplus plutonium, which is not in pure form, can be used as the cores of new reactors. Used fuel can be recycled indefinitely, with onsite facilities. The nitride fuel has been successfully tested in the BN-600 reactor to a burn-up of 7.4%.

A construction schedule for BREST was presented at a Proryv (Breakthrough) project meeting at the Siberian Chemical Combine (SCC) at Seversk in March 2013. NIKIET finished the BREST design in 2014 and working documentation was prepared in 2016, along with a preliminary report on the safety aspects of the whole project. A government decree in August 2016 ordered construction by 2025. RUR 25 billion ($809 million) was budgeted for the reactor and RUR 17 billion ($550 million) for the fuel cycle facilities. In November 2019 SCC awarded a contract to Titan-2 to build the demonstration (OD) BREST unit, in February 2021 Rostechnadzor issued a construction licence for it, and construction started in June 2021.

The demonstration BREST-300 unit is being built at SCC for completion in 2026. Initial operation will be focused on performance and after ten years or so it will be commercially oriented. If it is successful as a 300 MWe unit, a 1200 MWe (2800 MWt) version will follow – the BR-1200. The BREST reactor is an integral part of the Pilot Demonstration Energy Complex (PDEC or PDPF).

The State Environmental Commission of the Federal Service for Supervision of Natural Resources (Rosprirodnadzor) issued a positive statement on the construction licence application package for the Pilot Demonstration Power Facility (PDPF) and fuel fabrication module in June 2014. The PDPF or Pilot Demonstration Energy Complex (PDEC) comprises three elements: the mixed uranium-plutonium nitride fuel fabrication/refabrication module; a nuclear power plant with BREST-OD-300 reactor; and used nuclear fuel reprocessing module, the Fuel Recycling Facility (FRF). The combination enables a fully closed fuel cycle on one site.

SVBR

A smaller and newer Russian design is the Lead-Bismuth Fast Reactor (SVBR) of 75-100 MWe. This is an integral design, with the steam generators sitting in the same Pb-Bi pool at 340-490°C as the reactor core, which could use a wide variety of fuels. The unit would be factory-made and shipped as a 4.5m diameter, 7.5m high module, then installed in a tank of water which gives passive heat removal and shielding. A power station with 16 such modules was expected to supply electricity at lower cost than any other new Russian technology as well as achieving inherent safety and high proliferation resistance. (Russia built 7 Alfa-class submarines, each powered by a compact 155 MWt Pb-Bi cooled reactor, and 70 reactor-years operational experience was acquired with these.) In 2009 Rosatom set up a joint venture, AKME-engineering, to build a prototype 100 MWe SVBR reactor, but in 2018 the project was dropped. See also information page on Small Nuclear Power Reactors.

MBIR

At the Research Institute of Atomic Reactors (RIAR or NIIAR) in Dimitrovgrad, Rosatom is replacing the BOR-60 in the 2020s with the 100-150 MWt multi-purpose fast neutron research reactor (MBIR), with four times the irradiation capacity. This will be a multi-loop research reactor capable of testing lead or lead-bismuth and gas coolants as well as sodium, simultaneously in three parallel outside loops. It will run on vibropacked MOX fuel with plutonium content of 38%, produced at RIAR in existing facilities. A 24% Pu fuel may also be used. RIAR intends to set up an on-site closed fuel cycle for it, using pyrochemical reprocessing it has developed at pilot scale.

In September 2010 Rosatom said that the MBIR multi-function fast reactor program would be open to foreign collaboration, in connection with the IAEA INPRO programme, and in June 2013 an agreement with France and the USA was signed to this end. Rostechnadzor granted a site licence to RIAR in August 2014, a construction licence in May 2015, and completion was expected in 2020. Rosatom is inviting international participation. The full MBIR research complex is now budgeted at $1 billion, with the Russian budget already having provided $300 million from the federal target program. Pre-construction shares of 1% are being offered for $10 million, allowing involvement in detailed design of irradiation facilities. From 2020 the fee was to rise to $36 million per one percent share.

An artist's impression of MBIR (NIIAR)

OK

Russia also used OK-550 or BM-40A lead-bismuth cooled fast reactors of 155 MWt to power seven Alfa-class nuclear submarines in 1968-95. They were 1.5 times as efficient as its normal submarine power plants due to higher coolant temperature. They used very highly enriched uranium-beryllium fuel. Three steam loops drove twin turbines delivering 30 MW.

FNR developments in Japan

A significant part of Japanese energy policy has been to develop FBRs in order to improve uranium utilisation dramatically. From 1961 to 1994 there was a strong commitment to FBRs, but in 1994 the FBR commercial timeline was pushed out to 2030, and in 2005 commercial FBRs were envisaged by 2050. Subsequently, Japan’s nuclear energy policy now includes having a Generation IV sodium-cooled demonstration FNR in operation by 2025.

In 1999 Japan Nuclear Cycle Development Institute (JNC) initiated a program to review promising concepts, define a development plan by 2005 and establish a system of FBR technology by 2015. The parameters are: passive safety, economic competitiveness with LWR, efficient utilisation of resources (burning transuranics and depleted U), reduced wastes, proliferation resistance and versatility (include hydrogen production). Utilities are also involved.

Phase 2 of the study focused on four basic reactor designs: sodium-cooled with MOX and metal fuels, helium-cooled with nitride and MOX fuels, lead-bismuth eutectic-cooled with nitride and metal fuels, and supercritical water-cooled with MOX fuel. All involve closed fuel cycle, and three reprocessing routes were considered: advanced aqueous, oxide electrowinning and metal pyroprocessing (electrorefining). This work is linked with the Generation IV initiative, where Japan is playing a leading role with sodium-cooled FBRs.

In October 2016 METI’s Conference on Fast Reactor Development agreed that it would be technologically possible to develop a demonstration reactor using the experience obtained from the prototype fast breeder reactor (FBR) Monju and the experimental reactor Joyo, owned by the Japan Atomic Energy Agency (JAEA). It also affirmed the importance of international cooperation in such an endeavour, and was briefed on progress with France’s Astrid project. METI’s Agency for Natural Resources & Energy (ANRE) set out requirements for any new demonstration fast reactors.

In August 2014 JAEA, Mitsubishi Heavy Industries and Mitsubishi FBR Systems concluded a five-year agreement with the French Atomic Energy Commission (CEA) and Areva NP to progress cooperation on the French Astrid pool-type design (see above). After CEA’s Astrid programme was put on hold in August 2019, in January 2020 a second five-year agreement on the development of fast neutron reactors took effect. JAEA said that this would focus on safety, after the earlier joint R&D efforts made progress on fuel, severe accidents and other technology areas, and moved the Japanese plans from loop to pool-type concepts. JAEA in September 2020 described the sodium-cooled fast reactor as “one of the most promising technologies of all so-called fourth-generation nuclear energy systems because of its high reliability and favourable economics.”

Japan's Joyo experimental reactor which has been operating since 1977 with a succession of three cores, was boosted to 140 MWt in 2003, but has been shutdown since 2007 due to damage. After substantial upgrading, JAEA is aiming to restart it in 2021. JAEA said Joyo had irradiated around 100 MOX fuel assemblies during about 71,000 hours of operation, and was significant in Japan’s fuel cycle policy. It is a loop-type fast reactor.

The 280 MWe Monju demonstration FBR reactor at Tsuruga started up in April 1994, but a sodium leakage in its secondary heat transfer system during performance tests in 1995 caused it to be shut down for almost 15 years. About three tonnes of sodium leaked and caught fire. Its oversight passed to JNC, and a Supreme court decision in May 2005 cleared the way for restarting it in 2008, but this was delayed and it restarted in May 2010 before closing down again due to an ancillary mechanical problem. It has three coolant loops, used 198 MOX fuel assemblies surrounded by 172 blanket assemblies, and operated at 714 MWt, 280 MWe gross and 246 MWe net.

MEXT was reported to be in favour of persevering with Monju, while METI was keen to scrap it, partly to get rid of the bad image. The Fukui governor reminded the panel that Monju was positioned in the national Strategic Energy Plan to become an international research base for studies on waste volume reduction, the mitigation of danger, and other improvements to technologies related to nuclear non-proliferation. The cabinet rejected a FY2016 budget request from MEXT for JPY 10 billion to prepare Monju for restart. In December 2016 the government confirmed plans to decommission it, despite the Fukui local government being adamantly opposed to this. Both NRA and Fukui prefecture approved decommissioning plans in November 2017.

Monju (Japan Nuclear Cycle Development Institute)

Mitsubishi Heavy Industries (MHI) is involved with a consortium to build the Japan Sodium-cooled Fast Reactor (JSFR) concept, with breeding ratio less than 1. This is a large unit which will burn actinides with uranium and plutonium in oxide fuel. It could be of any size from 500 to 1500 MWe. In this connection MHI has also set up Mitsubishi FBR Systems (MFBR). The demonstration FR model was due to be committed in 2015 and on line in 2025, and a 1500 MWe commercial FR is proposed by MHI for 2050.

Japan's LSPR is a lead-bismuth cooled reactor design of 150 MWt /53 MWe. Fuelled units would be supplied from a factory and operate for 30 years, then be returned. Concept intended for developing countries.

A small-scale design developed by Japan's Central Research Institute of Electric Power Industry (CRIEPI) in cooperation with Mitsubishi Research Institute and funded by the Japan Atomic Energy Research Institute (JAERI) is the 5 MWt, 200 kWe Rapid-L, using lithium-6 (a liquid neutron poison) as control medium. It would have 2700 fuel pins of 40-50% enriched uranium nitride with 2600°C melting point integrated into a disposable cartridge or 'integrated fuel assembly'. The reactivity control system is passive, using lithium expansion modules (LEM) which give burn-up compensation, partial load operation as well as negative reactivity feedback. As the reactor temperature rises, the lithium expands into the core, displacing an inert gas. Other kinds of lithium modules, also integrated into the fuel cartridge, shut down and start up the reactor. Cooling is by molten sodium, and with the LEM control system, reactor power is proportional to primary coolant flow rate. Refuelling would be every 10 years in an inert gas environment. Operation would require no skill, due to the inherent safety design features. The whole plant would be about 6.5 metres high and 2 metres diameter.

The Super-Safe, Small & Simple – 4S 'nuclear battery' – system is being developed by Toshiba and CRIEPI in Japan in collaboration with STAR work in USA. It uses sodium as coolant (with electromagnetic pumps) and has passive safety features, notably negative temperature and void reactivity. The whole unit would be factory-built, transported to site, installed below ground level, and would drive a steam cycle. It is capable of three decades of continuous operation without refuelling. Metallic fuel (169 pins 10mm diameter) is uranium-zirconium or U-Pu-Zr alloy enriched to less than 20%. Steady power output over the core lifetime is achieved by progressively moving upwards an annular reflector around the slender core (0.68m diameter, 2m high). After 14 years a neutron absorber at the centre of the core is removed and the reflector repeats its slow movement up the core for 16 more years. In the event of power loss the reflector falls to the bottom of the reactor vessel, slowing the reaction, and external air circulation gives decay heat removal.

Both 10 MWe and 50 MWe versions of 4S are designed to automatically maintain an outlet coolant temperature of 510°C – suitable for power generation with high temperature electrolytic hydrogen production. Plant cost is projected at $2500/kW and power cost 5-7 cents/kWh for the small unit – very competitive with diesel in many locations. The design has gained considerable support in Alaska and and toward the end of 2004 the town of Galena granted initial approval for Toshiba to build a 4S reactor in that remote location. A pre-application NRC review is under way with a view to application for design certification in October 2010 (delayed from 2009 by NRC workload), and construction and operating licence (COL) application to follow. Its design is sufficiently similar to PRISM – GE's modular 150 MWe liquid metal-cooled inherently-safe reactor which went part-way through US NRC approval process for it to have good prospects of licensing.

The L-4S is Pb-Bi cooled version of 4S.

FNR developments in India

In India, research continues. At the Indira Gandhi Centre for Atomic Research a 40 MWt fast breeder test reactor (FBTR) has been operating since 1985. In addition, the tiny Kamini there is employed to explore the use of thorium as nuclear fuel, by breeding fissile U-233.

In 2002 the regulatory authority issued approval to start construction of a 500 MWe prototype fast breeder reactor (PFBR) at Kalpakkam and this is now under construction by BHAVINI. It was expected to be operating in 2017, fuelled with uranium-plutonium oxide (MOX – the reactor-grade Pu being from its existing PHWRs via Purex reprocessing) and with a thorium blanket to breed fissile U-233. The plutonium content would be 21% and 27% in two different regions of the core. Initial fuel will be MOX pellets, later vibropack fuel may be used.

The PFBR would take India's ambitious thorium program to stage 2, and set the scene for eventual full utilisation of the country's abundant thorium to fuel reactors. Six more such fast reactors are envisaged. FBR 1&2 of 600 MWe each with oxide fuel have been announced. Initial Indian FBRs would have mixed oxide fuel but these would be followed by metallic-fuelled ones to enable shorter doubling time. They would have a homogeneous core with two enrichment zones of mixed oxide fuel, plus blanket and reflector. Burn-up is 150 GWd/t and core breeding ratio is 1.11. Metal fuel is envisaged later.

India is also developing mixed carbide fuels for FNRs (U-Pu-C-N-O). Its FBTR has run on mixed carbide fuel since 1985 (70% PuC, 30% UC). Carbide fuel in the FBTR has demonstrated 165 GWd/t burn-up without failure, and has been reprocessed at pilot scale. Metal fuel is envisaged after 2020.

The Demonstration Fast Reactor Fuel Reprocessing Plant (DFRP) is being established to process both MOX and mixed carbide fuels, and a dedicated co-located Fast Reactor Fuel Cycle Facility (FRFCF) for PFBR is under construction.

Indian figures for PHWR reactors using unenriched uranium suggest 0.3% utilization, which is contrasted with 75% utilization expected for PFBR.

FNR developments in China

In China, R&D on fast neutron reactors started in 1964. A 65 MWt fast neutron reactor – the Chinese Experimental Fast Reactor (CEFR) – was designed by 2003 and built near Beijing by Russia's OKBM Afrikantov in collaboration with OKB Gidropress, NIKIET and Kurchatov Institute. It achieved first criticality in July 2010, can generate 20 MWe and was grid connected in July 2011. Core height is 45 cm, and it has 150 kg Pu (98 kg Pu-239). Temperature reactivity and power reactivity are both negative.

The CFR600 demonstration fast reactor (CDFR) is the next step in China Institute of Atomic Energy's (CIAE's) programme, with construction start in December 2017 at Xiapu in Fujian and operation envisaged from about 2023. A second unit started construction at the end of 2020. Each will be 1500 MWt, 600 MWe, with 41% thermal efficiency, using MOX fuel with 100 GWd/t burn-up, and with two secondary sodium coolant loops producing steam at 480°C. Later fuel will be metal with burn-up 100-120 GWd/t. Breeding ratio is about 1.1, design operational lifetime 40 years. This was CIAE's 'project one' CDFR. It is to have active and passive shutdown systems and passive decay heat removal.

CEFR (China Institute of Atomic Energy)

However, in October 2009 an agreement was signed with Russia's Atomstroyexport to start pre-project and design works for a commercial nuclear power plant with two BN-800 reactors in China, referred to by CIAE as 'project 2' CDFR, with construction to start in 2013 and commissioning 2018-19. These would be similar to the OKBM Afrikantov design being built at Beloyarsk 4 which started up in 2014. In contrast to the intention in Russia, these would use ceramic MOX fuel pellets. The project was expected to lead to bilateral cooperation of fuel cycles for fast reactors, but is apparently suspended.

The CFR1000 will be a commercial unit (CCFR) of 1000-1200 MWe. Subject to a 2020 decision to proceed, construction start could be in December 2028 and operation from about 2034, with metal U-Pu-Zr fuel and 120-150 GWd/t burn-up. An earlier design of this, the CDFR1000, was to be three-loop 2500 MWt pool-type, use MOX fuel with average 66 GWd/t burn-up, run at 544°C, have breeding ratio 1.2, with 316 core fuel assemblies and 255 blanket ones, and a 40-year operational lifetime. It is to have active and passive shutdown systems and passive decay heat removal. Some of these features may be in the CFR1000.

In December 2013 a US Federal Register notice said that the USA had negotiated an agreement with China “that would facilitate the joint development of TWR technology” from TerraPower, including standing wave versions of it. In September 2015 CNNC and TerraPower signed an agreement to work towards building a prototype 600 MWe TWR unit in China, apparently over 2018 to 2023. A commercial version, still called the Travelling Wave Reactor or TWR-C would be 1150 MWe, as phase 3 of the program. See fuller description below.

CIAE projections show fast reactors progressively increasing from 2020 to at least 200 GWe by 2050, and 1400 GWe by 2100.

CIAE announced first criticality of its Qixing/Venus III zero-power lead-bismuth fast reactor in October 2019, and said that marked the start of core physics R&D on the type as well as a transition from basic research to engineering for them. (Qixing I is a fast sub-critical accelerator-driven system – ADS used for transmutation research related to wastes, Qixing II is a lead-cooled zero-power fast reactor.)

FNR developments in South Korea

Closely related to its major research initiative on an advanced spent fuel conditioning process (ACP), and designed to be fuelled by the product of it, KAERI has proposed development of a pool-type sodium-cooled fast reactor, which will operate in burner (not breeder) mode. ACP will use electrometallurgical pyroprocessing to close the fuel cycle with oxide fuels which have been reduced to the metal on a commercial basis. (The pulverised used fuel is heated to drive off volatile fission products and then it is reduced to metal.) In a bath of molten lithium and potassium chloride, uranium is recovered electrolytically. The remaining tranuranics (Pu, Np, Am, Cm) are concentrated and removed with the remaining fission products (notably cerium, neodymium & lanthanum) to be fabricated into fast reactor fuel without any further treatment. This is intrinsically proliferation-resistant because it is so hot radiologically, and the curium provides a high level of spontaneous neutrons. Also it recycles about 95% of the used fuel. The ACP Facility (ACPF) at KAERI was built in the basement of the Irradiated Materials Experiment Facility (IMEF) for laboratory-scale demonstration of ACP.

This fast reactor proposal was supported by the USA in connection with GNEP/IFNEC and the Korean Prototype Generation IV sodium-cooled fast reactor (PGSFR) is planned for construction by 2028. Building on decades of cooperation already, a formal agreement with the US Argonne National Laboratory (ANL) was signed in August 2014 to progress this towards NSSC licensing approval by 2020 and commissioning by the end of 2028. The prototype of 392 MWt would produce 150 MWe for the grid, but its main purpose would be to demonstrate its fuel: PGSFR is to use metal fuel pins composed of low-enriched uranium and 10% zirconium, and it can be subsequently reloaded with fuel that also contains transuranic elements recovered from reprocessing used oxide fuels. The primary goal of PGSFR is to demonstrate the reduction of radioactive waste from spent conventional reactor fuel by transmuting radiotoxic and long-lived elements.

Regarding safety, Argonne said that "the metal fuel technology base was developed at Argonne in the 1980s and 1990s; its inherent safety potential was demonstrated in the landmark tests conducted on the US Experimental Breeder Reactor-II (EBR-II) in April 1986. They demonstrated the safe shutdown and cooling of the reactor without operator action following a simulated loss-of-cooling accident… The PGSFR is the world's first fast reactor that exploits inherent safety characteristics to prevent severe accidents."

South Korea's KALIMER (Korea Advanced Liquid Metal Reactor) concept is a 600 MWe pool type sodium-cooled fast reactor designed to operate at over 500°C. It has evolved from a 150 MWe version. It has a transmuter core consisting of uranium and transuranics in metal form from pyro-processing, and no breeding blanket is involved. KALIMER-600 is expected to serve as a reference design for the technology development of Generation IV sodium-cooled fast reactor systems and in the commercialization of one in South Korea.

Another stream of fast reactor development is via the Nuclear Transmutation Energy Research Centre of Korea (NuTrECK) at Seoul University (SNU), drawing on Russian experience. It is working on lead-bismuth-cooled designs of 35, 300 and 550 MW which would operate on pyro-processed fuel. The 35 MW unit is designed to be leased for 20 years and operated without refuelling, and then returned to the supplier. It would be refuelled at the pyro-processing plant and have a design life of 60 years.

FNR developments in the USA

Through to 1985 the US Department of Energy spent about $16 billion (2011 $) on sodium-cooled fast reactors, a large proportion of its R&D budget.

EBR & IFR

In the USA, five fast neutron reactors have operated, and several more designed. The experimental breeder reactor EBR-1 at Idaho was designed to validate the physics of breeding fuel. Incidentally, in 1951 it produced enough power to run its own building – a milestone achievement. By 1955 the reactor had fulfilled its main experimental purposes, and was tested further by restricting coolant flow, which caused a core melt. The reactor was rebuilt with a new, slightly different core and ran to the end of 1963. It was declared a National Historical Landmark in 1965.

The EBR-II was a demonstration reactor – 62.5 MW thermal, and it typically operated at 19 MWe – providing heat and over 2 TWh of power to the Idaho facility over 1963-94. The idea was to demonstrate a complete sodium-cooled breeder reactor power plant with onsite reprocessing of metallic fuel, and this was successfully done in 1964-69. The emphasis then shifted to testing materials and fuels (metal and ceramic oxides, carbides and nitrides of uranium and plutonium) for larger fast reactors. Finally it became the IFR prototype, using metallic alloy U-Pu-Zr fuels, and it pioneered the closed fuel cycle, which involved remote handling at all stages through fuel fabrication. Several fuel cores were made for EBR-II, using high-active materials. All the time, it generated some 1 TWh of power as well.

The EBR-II was the basis of the US Integral Fast Reactor (IFR) programme, considered by the National Academy of Sciences to be the nation's highest priority research for future reactor types. This was developing a fully-integrated system with electrometallurgical 'pyroprocessing', fuel fabrication and fast reactor in same complex*. The reactor could be operated as a breeder or not. Some $46 million of the IFR funding was provided by a Japanese utility consortium.

* So far the only electrometallurgical technique that has been licensed for use on a significant scale is the IFR electrolytic process developed by Argonne National Laboratory and used for pyroprocessing the used fuel from the EBR-II experimental fast reactor which ran from 1963-1994.

IFR programme goals were demonstrating inherent safety apart from engineered controls,* improved management of high-level nuclear wastes by recycling all actinides, so that only fission products remain as HLW,** and using the full energy potential of uranium rather than only about one percent of it. All these were demonstrated, though the program was aborted in 1994 before the recycle of neptunium and americium was properly evaluated. IFR fuel first used in 1986 reached 19% burnup (compared with 3-4% for conventional reactors), and 22% was targeted.

* In April 1986, two tests were performed on the EBR-II. In the first, the main primary cooling pumps were shut off with the reactor at full power. Without allowing the normal shutdown systems to interfere, the reactor power dropped to near zero within about five minutes. No damage to the fuel or the reactor resulted. The second test was again with the reactor at full power, and the flow in the secondary cooling system was stopped. This caused the reactor temperature to increase, and as the fuel, primary sodium coolant and structure expanded, the reactor shut down on its own.

** for a 1000 MWe plant at 90% capacity factor about 990kg/yr of HLW is projected.

A further political goal was demonstrating a proliferation-resistant closed fuel cycle, with plutonium being recycled with other actinides.

In 1994, Congress under the Clinton administration shut EBR-II down, and aborted the IFR three years before its commissioning, delivering a major setback to FNR fuel cycle developments. In 2001, as part of the Generation IV roadmap, the DOE tasked a 242 person team of scientists from DOE, UC Berkeley, MIT, Stanford, ANL, LLNL, Toshiba, Westinghouse, Duke, EPRI, and other institutions to evaluate 19 of the best reactor designs on 27 different criteria. The IFR ranked first in their study which was released in April 2002.

The IFR programme is now being reinvented as part of the Advanced Fuel Cycle Initiative (see below), while EBR-II is being decommissioned. An EBR-III of 200-300 MWe was proposed but not developed.

Other early FNRs in USA

The first US commercial FBR was Fermi 1 in Michigan, but it operated for only three years before a coolant problem caused overheating and it was shut down with some damage to the fuel. After repair it was restarted in 1970, but its licence was not renewed in 1972. Its cooling system did not enable it to operate at or near full power of 60 MWe net.