How is used nuclear fuel managed?

- Used nuclear fuel is responsibly managed to protect people and the environment, using well-established and proven industrial methods and technologies.

- Management of used fuel encompasses its storage, transport, re-use and disposal.

- Used nuclear fuel is not classed as waste while the option of reprocessing remains open.

- The risks of managing used fuel are comparable to other toxic industrial materials; unlike these materials, these risks decrease over time due to radioactive decay.

- It is usually in the form of solid pellets contained within hollow metal tubes, held together in a nuclear fuel assembly; its shape remains unaltered during its use in a reactor.

- Used nuclear fuel is produced in small quantities relative to the massive energy it generates, and leaves a modest waste stream compared to other forms of electricity generation.

What is used nuclear fuel?

Nuclear fuel typically stays in a reactor for several years, generating heat from the fission of U-235 and fissile plutonium. Over time, the level of fission products and other neutron absorbers builds in the fuel, disrupting the fission chain reaction. As such, about one-third of the fuel is changed in a reactor every 12 to 18 months.

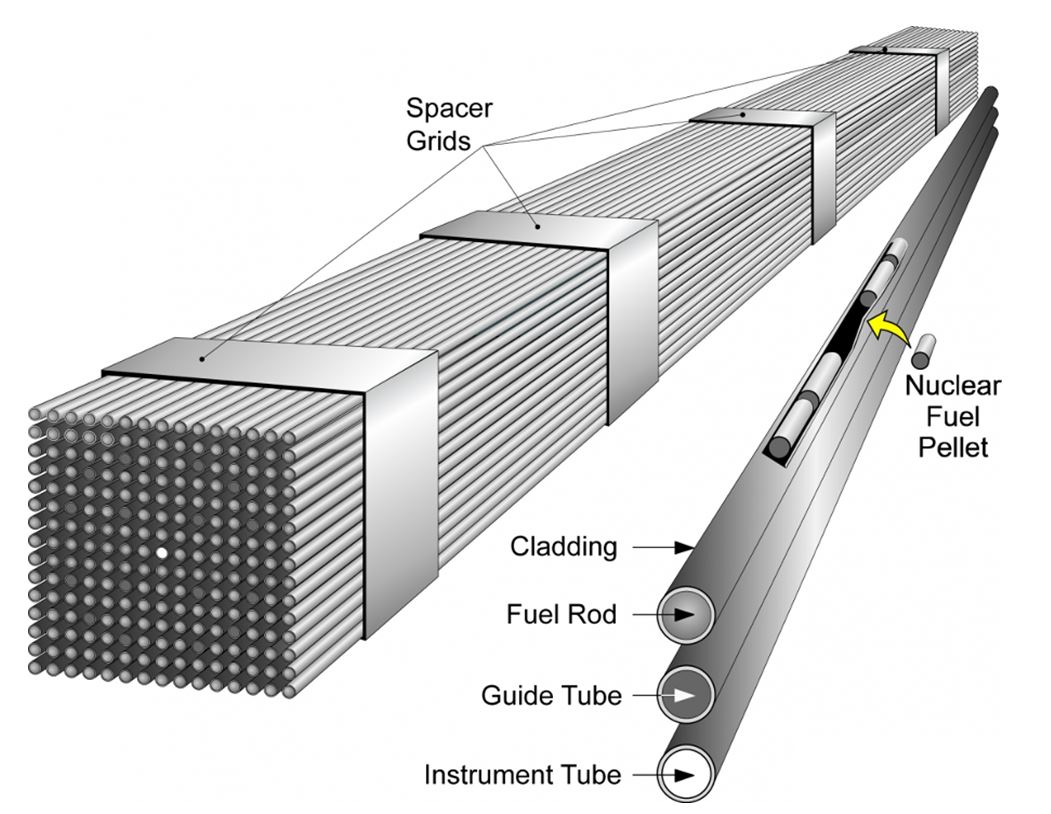

Used nuclear fuel has the same shape and appearance as fresh nuclear fuel. The fuel itself is usually pelletized, and held in metal rods as part of a fuel assembly or "bundle". The number of fuel assemblies varies by reactor. A large pressurised water reactor typically has 150-250 fuel assemblies, each containing 200-300 fuel rods.

Nuclear fuel schematic (Image: United States Department of Energy)

Cooling ponds and dry casks

Upon removal from the reactor core, used fuel is hot and radioactive. All used fuel is therefore transferred to purpose-built water cooling pools or "ponds" at the reactor site, where it is kept for at least a few years. The water allows heat to dissipate, and provides an effective shield from radiation. In some countries, such as Sweden, used fuel is transferred to centralised storage pools after initial cooling.

Central Interim Storage Facility (CLAB), Sweden (Image: SKB)

In other countries, most used fuel that has undergone initial cooling is transferred to dry storage systems. Cask-based storage is the most common dry system. Storage casks may be at the reactor site, such as in the United States, or at a centralised facility, such as in Switzerland. In order for fuel to be transferred, it must meet strict radiological, thermal and chemical requirements. Dry storage casks typically hold about 20 fuel assemblies, and are cooled by natural circulation. There has not been any significant radioactive release from used nuclear fuel in dry cask storage or "ponds".

Dry Cask Storage at Vermont Yankee, USA (Image: Vermont Yankee)

Loading of NUHOMS Storage Cask, United States (Image: TN International, Orano)

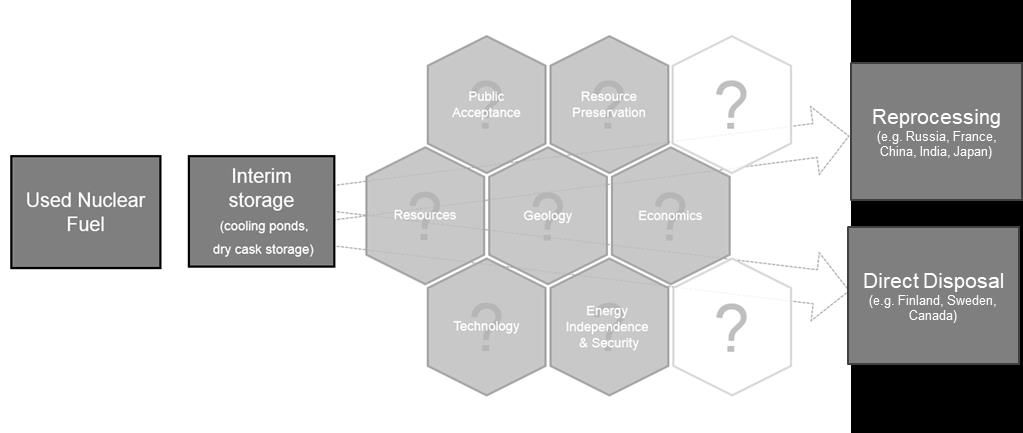

Long-term management

The longer used fuel is stored, the lower its radioactive hazard due to decay. At some point, however, a decision must be made to reprocess used fuel in order to recycle its usable components, or to classify it as a waste and prepare for its disposal.

The decision is a strategic one taken at a national level, and involves consideration of multiple factors.

Long-term management - example policy factors (Image: World Nuclear Association)

Reprocessing / recycling

It is a special characteristic of nuclear energy that its used fuel can be reprocessed to recover valuable material for reuse. At present, about one third of used fuel is bound for reprocessing. Russia, China, France, India and Japan all have policies to reprocess used nuclear fuel, avoiding the wastage of a valuable resource.

Reprocessing used fuel brings about a number of significant benefits, including, but not limited to:

- Approximately an 80% reduction in the volume of material for final disposal as high-level waste

- A reduction in the radiotoxicity of waste for final disposal

- Improved recovery / utilisation of energy from the original uranium, enhancing sustainability and national security

- Recovery of valuable material for use in medicine and other industries

The high-level waste that is separated during reprocessing is engineered into a stable material such as glass for final disposal.

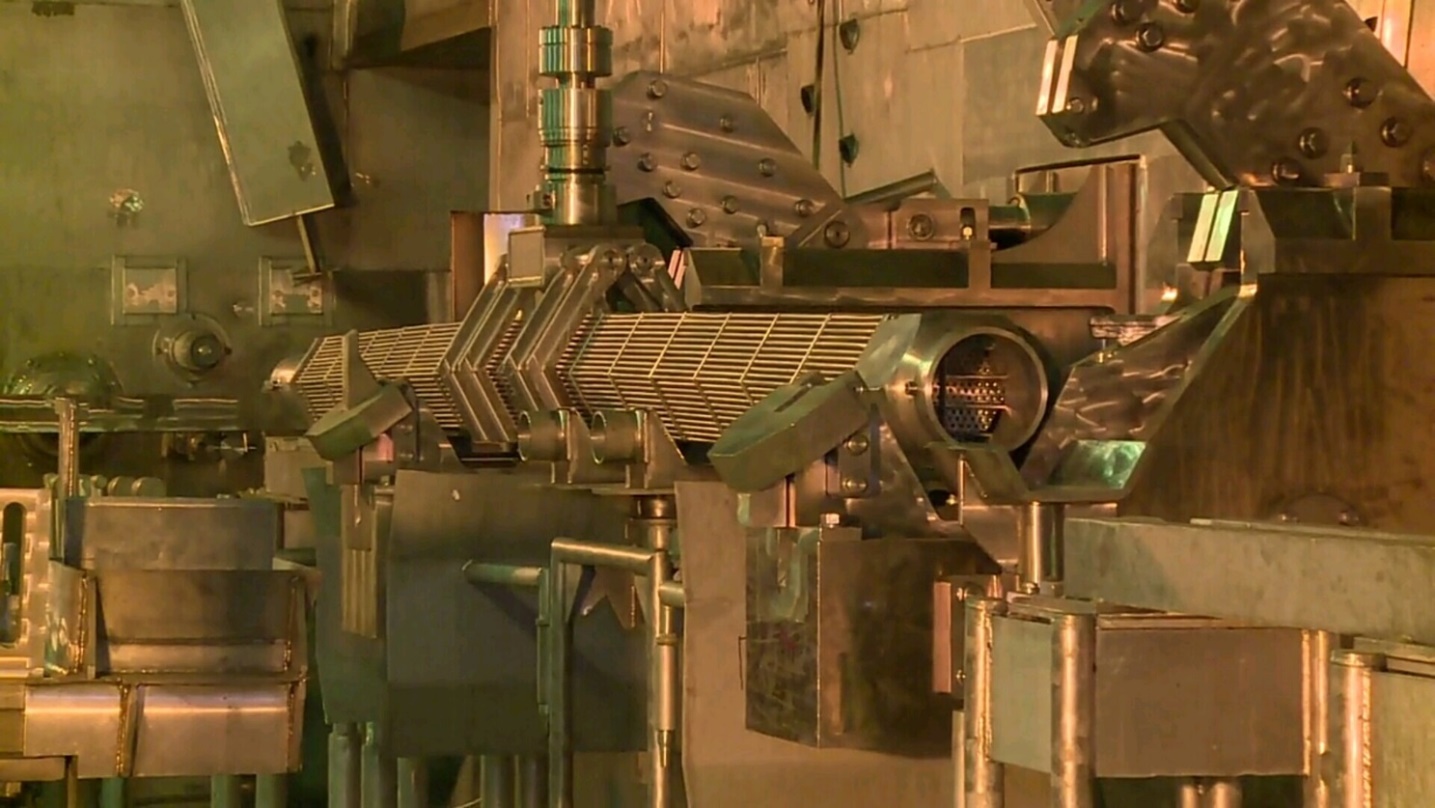

Used nuclear fuel assembly cutting prior to dissolution at Mayak Plant, Russia (Image: Rosatom)

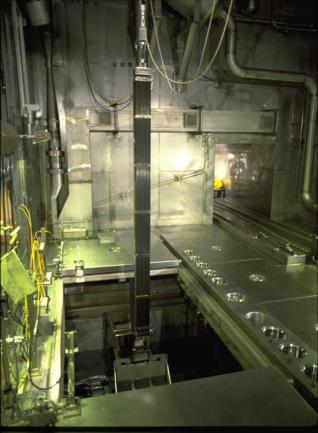

Fuel assembly being lowered into the cooling pit in T0 dry loading facility, France (Image: Sidney Jezequel, Orano)

Disposal

Reflecting scientific consensus, the International Atomic Energy Agency (IAEA) considers emplacement in a deep geological disposal facility (GDF) to be the best option for safe management of used nuclear fuel and high-level waste. GDFs achieve isolation through a combination of engineered and natural barriers, and are designed such that no obligation to actively maintain the facility is passed on to future generations.

GDFs are currently used for the disposal of other toxic wastes, including those containing mercury, cyanide, arsenic and dioxins. A purpose built deep geological repository for disposal of nuclear material, the Waste Isolation Pilot Plant (WIPP), is in operation in the USA, but it is not licenced for disposal of used nuclear fuel or high-level waste.

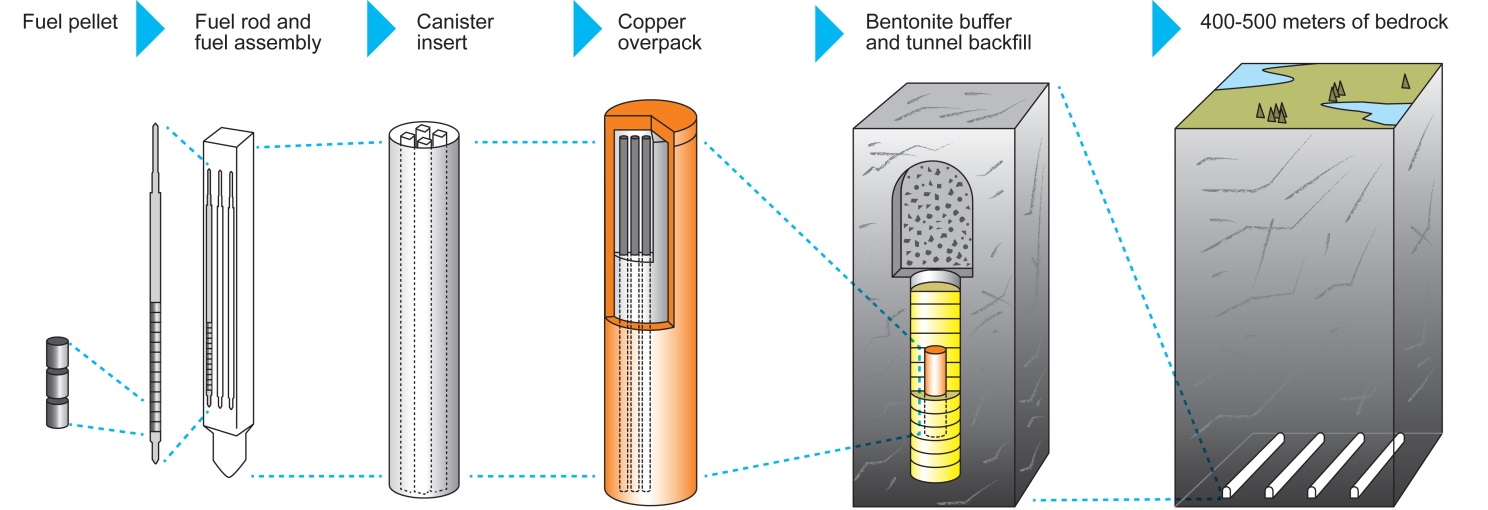

Plans for GDFs for used nuclear fuel and high level waste are well advanced in a number of countries, most notably Finland and Sweden. GDFs in Sweden and Finland envisage used fuel being placed in copper canisters with cast iron inserts to hold the assemblies in place. The canisters are to be located deep underground within a geologically stable rock structure. An impermeable backfill material, such as bentonite clay, will be used to surround the canisters to limit water movement and delay migration. Different host rock types, such as clay or salt, are under consideration in other countries.

Multi-barrier disposal concept (Image: Posiva)

Quantities

Nuclear fuel is energy dense – approximately a million times more so than coal. Consequently, the amount of fuel required – and thus the amount of used fuel created – is relatively small.

The United States has been generating electricity from nuclear power since 1958, and it currently produces more nuclear electricity than any other country. If all the used fuel assemblies that have been discharged from the country's nuclear reactors were placed on a soccer pitch, they would reach a height of approximately 15 metres.

Transport

The management of used fuel involves its transport, which commonly takes place between nuclear plants and centralised storage and reprocessing facilities. Used fuel is transported in robust, rigorously-tested 100 tonne containers by road, rail or sea. In the last half century, there have been thousands of shipments of used fuel transported globally. There has been no instance of radioactive release causing harm to people, property or the environment in many millions of transport miles.

Whilst transport of used nuclear fuel is well-practiced, such consignments make up a very small proportion of all radioactive material transport; the majority contain radioisotopes for medical and industrial use.

Mox fuel assembly being loaded into a transport container, France (Image: Eric Larrayadieu, Orano)

Road transport of used fuel, Japan (Image: Nuclear Fuel Transport Ltd.)

Arrival of Mox shipment from France to Japan (Image: Kansai Electric Power Company)

Financing used fuel management

Nuclear power is the only energy-producing technology that takes full responsibility for its waste and makes financial provisions for the cost of their management and disposal.

Most nuclear utilities are required by governments to put aside a levy (e.g. the Nuclear Liabilities Fund in the UK) to provide for the management of their used nuclear fuel up to final disposition of the final waste. These funds are monitored carefully by independent third parties and contributions are regularly adjusted if needed.

Continuous improvement

The techniques in practice to manage used nuclear fuel today are well-established, reflecting the industry's long-standing recognition of the importance of sustainable back-end operations. As the industry grows, it continues to invest to enhance existing – and to find new and innovative – techniques to maximise sustainability.

Maintenance of AMEC Cask (Image: Eric Larrayadieu, Orano)